Thermoplastic granulation / Melt granulation:

In this process

moldable binders are used which acts as solids in room temperature but melts

down at temperature between 50°C to 80°C

and behaves as liquid binder, there is no drying phase. Dried granules are

simply achieved by cooling them down at room temperatures.

3 phases are included.

1. wetting and nucleation.

2. coalescence

3. Attrition and

Breakage

1. Wetting and Nucleation

In this step liquid medium comes in contact with powder medium and small agglomerates are formed. Mathiesen and Schafer proposed 2 methods of nucleation

A. Immersion which

includes deposition of solids onto molten binder.

B. Distribution

includes formation of nuclei when particals comes in contact with binder,

through collision method.

2.Coalescence

This stage has nuclei

that has residual liquid for fusion of other nuclei

3.Attritution – breakage:

It refferes to have

granulation fragmentation. It has greater effect on the resulting properties.

Meltable Binders:

- Must be solid at room temperature and melts between 40-80 °C.

- Must be physically and chemically stable at various ph and moisture.

- Its HLB ensures correct release of active ingredients.

- Safe applications in humans.

Foam Binder Granulation (FBG):

In this type of

granulation aqueous foams are used in place of liquids. It has various benefits

over other wet granulation techniques it requires less wetting agent i.e. foam,

water sensitive compounds can be processed, drying time is reduced, no plugging

problems, less binders are requires in case of CR and SR products.

Novel technologies:

Spray dry granulation:

It is a continuous

process in which dried product is obtained in a process in which binding

solution or suspention of active pharmaceutical ingredient with or without

addition of excipients is feeded to the dried system which is then automized

and dried out with the help of heated gas-stream and the product is

subsequently separated from the stream. After that agglomeration of particles

is achieved by spry of binding solution onto the powder bed in fluidized state

by passage of hot air followed by drying. This technique is used in the

preparation of dusting powders and dry syrups. It is continuous and cost

effective process and the operator is less prone to dusting problems. It also

have some disadvantages that the thermolabile products cannot be prepared. And

particle size variation can occur in

case of improper spray.

Freeze granulation:

This technique

results in free flowing, homogenous and spherical granules. Spraying of powder

containing suspension is involved into the liquid nitrogen, where the resultant

drops are frozen instantaneously to form granules which upon freeze dying

yields dry granules. This is used in production of granules for injectable

purposes. By this process density of the granules can be controlled. Metals and

non oxides can be treated well through this process. It yields solid granules

with no cavaties. The organic solvent which is used in this process can be

recycled. And cleaning of equipments is very easy. It also has some of

disadvantages over other techniques i.e. degradation of drug can be occurred

due to freezing temperatures.

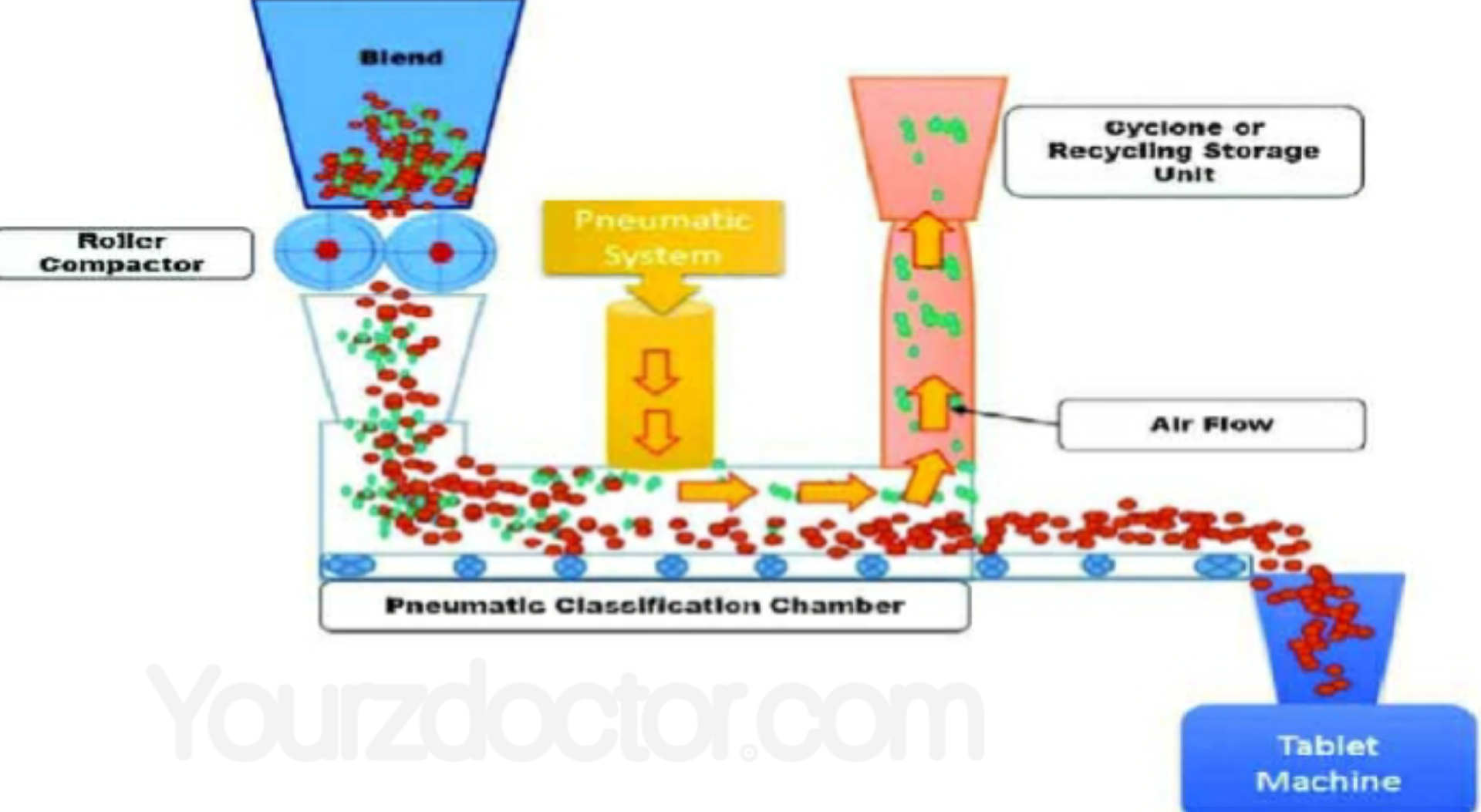

Pneumatic Dry Granulation (PDG):

It is a novel

granulation method which involves semi-automatic or complete automatic

production of granules. This process was invented by Atacama labs of Finland.

Compact mass is produced by roller compaction and then introduced into new

designed fractionating device which separate granules and recycles the rejected

fraction. It involve modification of disintegration time, hardness of tablet

and drug loading. High drug loading is achieved it easily masked taste of the

API and the difficult APIs combinations can be treated well, excellent

flowabilty and compressibility characteristics can be achieved.

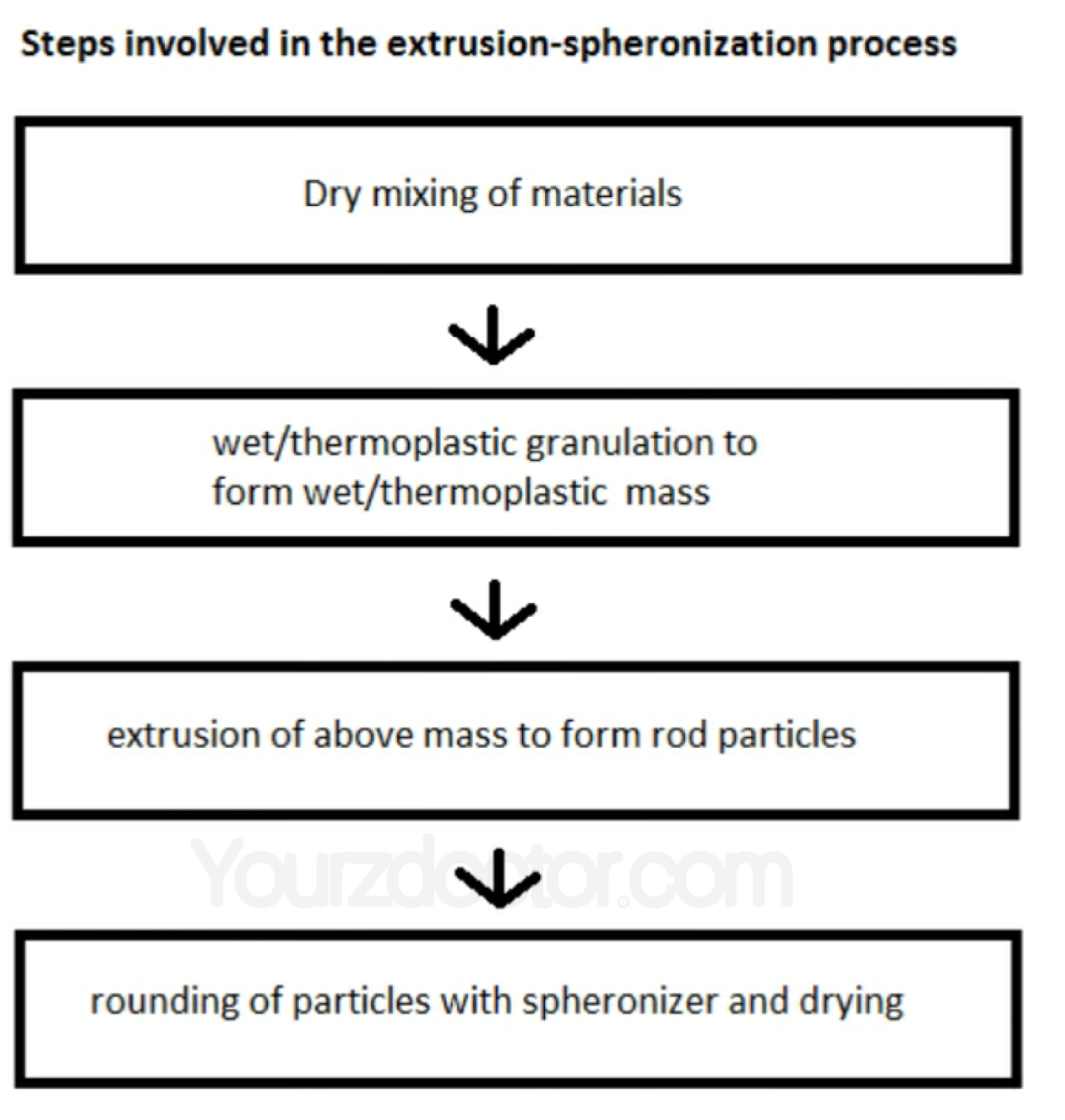

Extrusion-spheronization granulation process:

As the name indicates Extrusion is the process which is used to create objects with a

fixed cross-sectional profile. The material is passed through a die of desired cross section. Spheronization is

a process in which extrudates are shaped into the small spherical or rounded

granules. This process is used to make uniform particles which are very much

suitable for the manufacturing of controlled release or modified formulations.

Tacky mass is passed through extruder and pellets are formed by apply hot melt

or wet extrusion techniques. The parameters like pore size of extruder, speed

of spheronization and operational conditions should be controlled which can

influence the size of particles and granuler morphology. This technique is used

in the manufacturing of capsules, dry suspensions, tablets and dry powders. It

cannot be used for thermolabile and moisture sensitive materials.

For types of granulation technology click here

Learn more

Searching Tags

Novel granulation

technologies

Top 5 novel

granulation technologies

What is Thermoplastic granulation ?

What is Melt granulation?

Phases of melt granulation

Top 3 phases of wet granulation

What is Wetting ?

What is Nucleation ?

What is Coalescence?

What is Attritution ?

What is breakage in wet granulation?

What is Meltable Binders?

What is Foam Binder Granulation? What is FBG?

What is advance granulation technologies?

What is novel granulation technologies?

What is Spray dry granulation?

What is Freeze granulation?

What is Pneumatic Dry granulation? What is PDG?

What is Extrusion-spheronization granulation process?

How Extrusion-spheronization granulation process is performed?

0 Comments